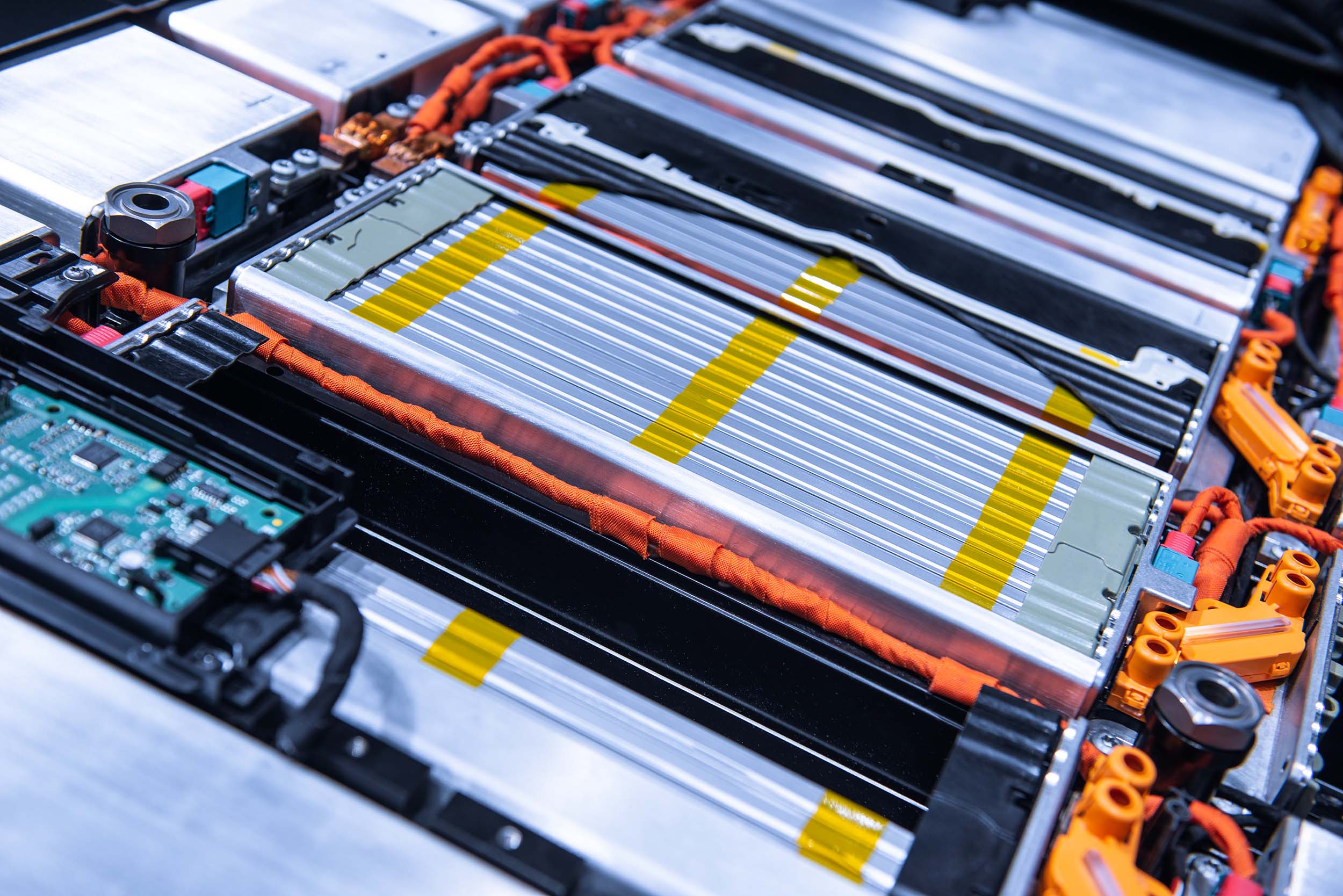

Battery production is a rapidly growing industry. But the lack of rigorous, verifiable, and disaggregated information about individual battery mineral emissions is a major problem that must be tackled. Depending on the mineral, deposit, and method, producing the metals for EV batteries can be highly emissions intensive – as is the case with nickel. The majority of the greenhouse emissions come from refining these minerals.

Manufacturing battery cells is also energy intensive, and will release significant quantities of CO2 emissions where renewable energy is not used. The World Economic Forum’s base case scenario for the battery value chain places its annual emissions by 2030 at 182 metric tonnes of CO2 – more than the current annual emissions of the Netherlands. Displacing ICE vehicles and carbon-based energy production would prevent far more yearly emissions overall, but minimizing battery emissions – from mine to manufacturing – is nonetheless a critical step for automakers if they are to stay on a 1.5 degree pathway as they scale up EV production.

Without stringent environmental protections, mining and refining minerals can cause deforestation, threaten biodiversity, pollute air and waterways, and leave toxic tailings (rock waste). If automakers and other industries don’t clean up battery supply chains as the world electrifies, then environmental degradation could discredit the transition to EVs.

Automakers need to start addressing these challenges now as new regulations, such as the EU battery law, will start requiring it.